Infrastructure

The credit of making our organization successful goes to our well coordinated and hard working

staff combined with the power of modern infrastructure. Our Production systems are organized

in a way such that it can produce the minutest of details that is required in a product with high

precision. Our state of the art infrastructure has enhanced the productivity of our workflow and

allowed us to achieve consistent quality standards giving us monumental edge over our

competitors. The handling of resources is also taken very seriously in the organization for which

independent warehousing facilities have been set up for individual working units. This ensures

that any necessary material required for production is readily available to complete multiple

orders at any given point of time. Our facilities our integrated in such a way that it facilitates the

complete process of garment manufacturing in house from the fabric cutting, finishing to

packing.

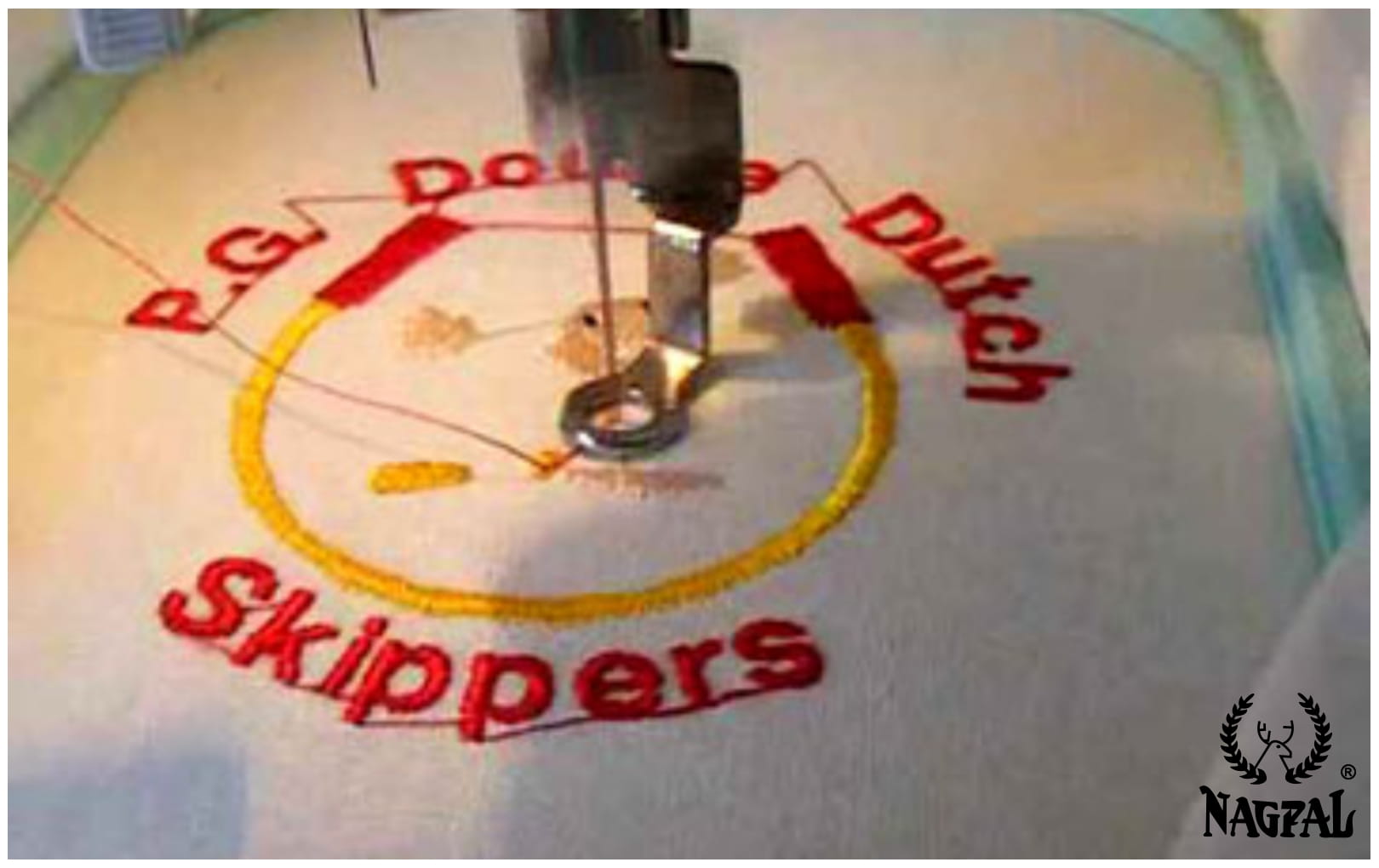

Our Production Facilities are Fully Equipped with State of the Art Manufacturing Facilities like

Computer/Hand operated Flat Bed Machines, Sewing Linking, Overlock,Button Stitch, Button

Hole Stitch, Bar Tacking, Thread Cutting Machines and Computer In-house Garmen Dying,

Stone/Enzyme Wash Process, Washing, Drying Tumblr, Steam Presses, high speed rapier

looms,octopus printing machines and Finishing Plant with latest Laboratory Equipment for

Quality Control and Sampling

We also have in Operation Needle Detection Equipment put in use at the Point of Packing to

ensure that goods are 100% safe to wear before Dispatch. Our Workforce Consisting of

Designers, Experts Skilled Workers is the Mainstay for our Continued success. Highly skilled

and experienced People work, Measuring up, each day, to growing and Changing International

Fashion trends

Due to such strong infrastructure backing us we are able to achieve numerous production

capacities across our brands. The flagship company Nagpal exports is exporting its garments

around and across the nation in more than 40 countries. It is a garment manufacturing unit

having the capability of manufacturing 20000 cotton garments, 2000 knitwear sweater every

day. The unit has computerized knitting machines imported from Germany, Italy, Japan, China

allowing it to perform the most demanding of tasks with ease.

The Knitting facility under our brand Ludhiana knit tech pvt ltd. brand is able to produce 40 tons

of knit fabric a day of products like Single Jersey, Double Jersey, Ribs and Polo Knits. The plant

is equipped with knitting machines ranging from 4 Gauges to 40 Gauges allowing it to knit

across variety of garments available. The company has huge capacity to produce cotton blends

ranging from 80GSM to 350GSM. We have both Circular and Warp knitting machines producing

all kind of knit fabrics and delicate synthetic knits including lycra. Similarly, our oasis knitwear

brand has a manufacturing capacity of more than 7000 garments and 2000 woolen and blended

garments and is actively exporting products across 35 countries.

Environment Focus

We at Nagpal Exports feel that it is our responsibility to look after the place which has given us the immense opportunity to perform amazing tasks everyday our mother Earth. We are very proud to host such infrastructure which is capable of minimizing our waste water production and helps sanitize the waste to a level that it can be disposed of safely. The Dyeing plant under our venture B.lall overseas has an active effluent treatment plant and recycling plant which ensure that the waste water produced due to the dyeing process is safe to release. We have set team of technicians which monitor the waste treated in the effluent plant(ETP). A final organism survival test is done to ensure the success of treatment in which fish are released into the treated water and then these are monitored to see their heath is intact and not affected by the water. The water is further used for irrigation of our plantation. Our plantation comprises a variety of trees. The addition of new plants take place periodically in order to maintain the green coverage around the area of our facility in an area spread across 7 acres. Also the hosiery waste is recycled and reused by the aid of our spinning plant. The waste is crushed and chemically glazed then its processed through the spinning unit to produce yarn from which further production activity takes place.